What's the carbonization process in carbonization furnace?

- 2019-11-08 16:41:00

- E.P Machinery Original

- 2198

What’s carbonization?

Carbonization also called destructive distillation, is a pyrolys is process transferring biomass materials into charcoals under conditions of anoxic or oxygen-poor. This is a process only involves temperature and water vapor, no chemical additives or foreign substances. In this process, complex substances (wood) would break down into recyclable simpler ones (water, tar, and carbon coke). Therefore, carbonized wood is very safe and environment-friendly. It is an environmentally friendly material.

What’s carbonization?

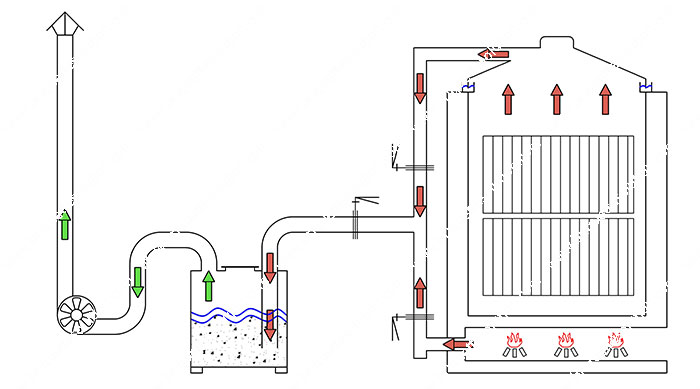

Carbonization Furnace

What happened during carbonization in carbonization furnace?

There are two kinds of carbonization furnaces. One is hoisting carbonization furnace, and the other is rotary drum carbonization furnace. These two kinds machine basically have the same carbonization process but suits different raw materials. The following content is about the carbonization process.

First stage — drying.

The first step in carbonization is to dry out the wood in charcoal kiln under 100°C. This process would consume a lot of energy and spend a quiet long time because no recyclable flammable gases are produced. To save energy and improve carbonization efficiency, we recommend you use the sun to pre-dry the wood as much as possible before putting materials into the kiln.

Second stage — initial carbonization.

When the wood is bone dry to zero water content, the temperature of the kiln would raise to about 280℃. At this time, the wood starts pyrolysis, and its composition starts to change, among which, the unstable compositions, such as hemicellulose, decompose into CO2, CO and a small amount of acetic acid.

wood and lump charcoal

Third stage — fully carbonization.

During the last process, air is deliberately released into the kiln, where oxygen is combusted into carbon dioxide, and the nitrogen remains in the kiln. This process is also called an exothermic reaction. As the exothermic reaction continues, the temperature in the kiln will at 280 °C-400°C and the wood turns into charcoal. This charcoal, however, contains about 65-70% fixed carbon, 3-5% ash and high volatility. The volatiles of different tree species may be different, but generally, do not reach 30%.

Forth stage — calcine.

Further heating will increase the fixed carbon of charcoal and decompose the volatiles. The temperature in the kiln will reach 500 °C, the carbon content of charcoal will rise to about 85%, and the volatile content will drop to about 10%. The charcoal content at this temperature drops to about 33% by weight of the wood.

Good commercial charcoal is often carbonized at the temperature of about 500 °C, with a fixed carbon content of about 75%. If the wood is carbonized at low temperatures, the charcoal would contain too many volatiles and when it burns it would have a flame and generate acidic smell. There are many factors affecting charcoal yield and charcoal conversion rates, so we should try every method to avoid the factors that may cause the problem.

| Contacts : | Chris Wang |

|---|---|

| Phone : | +8613633713237 |

| Email : | chris@ep-machine.com |

| Wechat : | +8613633713237 |

| Whatsapp : | +8613633713237 |

| SNS : |

|