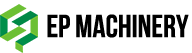

Hydraulic Shisha Charcoal Briquette Machine

Details

Product Description

Hydraulic shisha charcoal press machine, also known as hookah charcoal briquette making machine. It is a professional equipment to compacting charcoal fines mixed with binder, especially coconut shell charcoal into different shapes such as cubic or round charcoal tablets for shisha/hookah.

The shisha charcoal press machine is equipped with a hydraulic pump station, and the customers could adjust the molding pressure and the density of charcoal tablets according to their requirements. It is currently the best-selling hookah charcoal tablet press machine on the market, especially in the Middle East and Southeast Asia.

Finished Products

Finished Shisha Charcoal Briquettes

The finished shisha charcoal tablets produced by this machine are with high density, perfect shape, good appearance. Meanwhile, it is easy for combustion, no smell and long burning time. Because the mould is customizable, customers can make different shapes of charcoal tablets based on their demand. Normally, the cubic shape 25*25*15mm and 25*25*25mm is the most popular in the market.

Raw Material

Applicable raw materials

The raw material can be charcoal, coal, coke etc. In addition, if the raw material is biomass with lignin, such as coconut shell, bamboo, rice husk, sawdust etc. E.P company can supply different carbonization equipment to help customer carbonize the raw material into charcoal for pressing

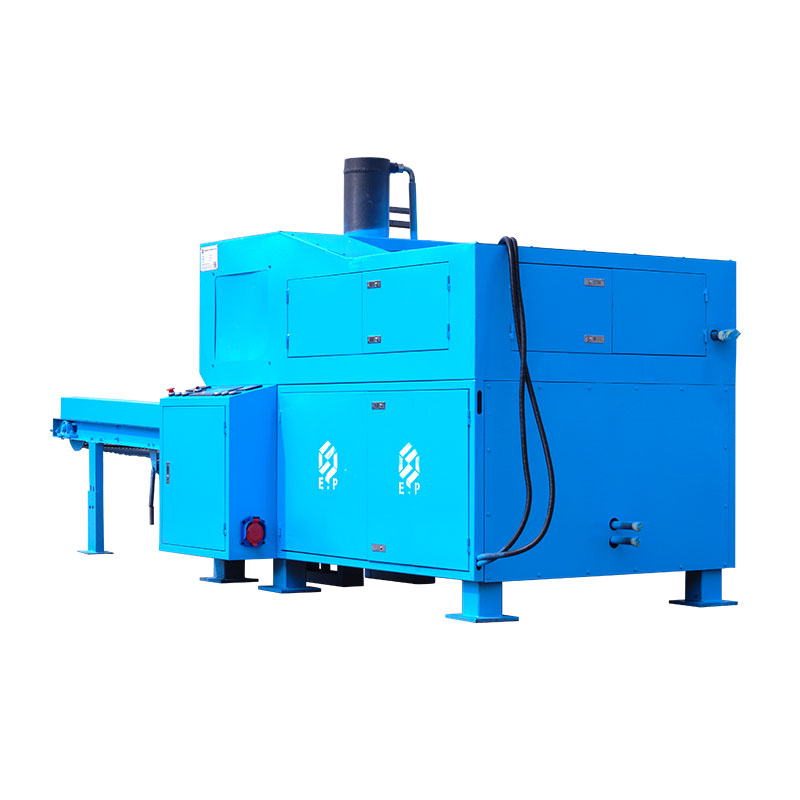

Workflow

Through the high extruding pressure during the pressing process, the raw material charcoal powder and binder will be pressed into solid charcoal briquettes. The basic processes are list as below. Not all these processes are necessary, it all depends on the situation of your raw materials. Please don’t hesitate o contact with us if you need any suggestion on charcoal briquettes production.

The workflow is like this:

Charcoal Pressing Tablets

Biomass Material Pressing Tablets

We can customize different production line proposals according to the specific requirements of customers. The following flowchart only for reference.

Advantages & Features

1. Hydraulic Pump Station

Advanced hydraulic pump station. The shisha charcoal press is equipped with an advanced hydraulic pump station, hydraulic oil can be cooled effectively, to keep high and stable pressure. The resulting charcoal briquettes have high strength, not be broken during operation.

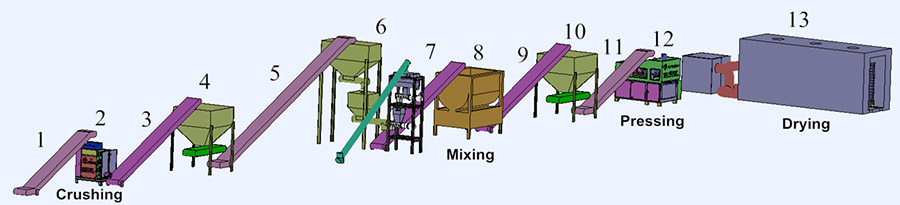

2. PLC Control Panel

PLC control. The touch screen on the cabinet can show the working condition. It is very convenient to operate the machine and adjust the parameters. Besides, the machine can also run full-automatically.

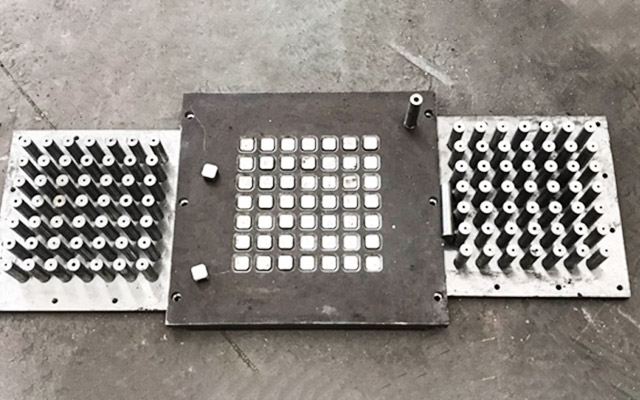

3. High Quality Mold

High-quality and accurate moulds. The moulds are produced by large CNC machine tool, the moulds are very accurate, the resulting charcoal briquettes have perfect shape and smooth surface.

4. Safety Plug

ASTM&EU standard Plug and Socket, to make it more convenient and safe to connect machine with power.