Rotary Charcoal Carbonizing Furnace

Details

PRODUCT DESCRIPTION

Charcoal Carbonizing Furnace

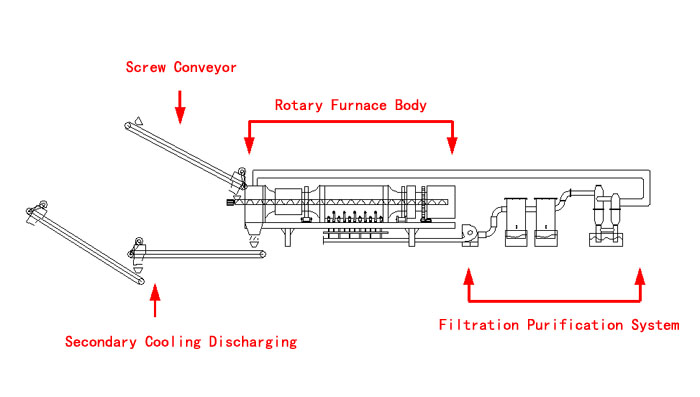

The rotary charcoal carbonizing furnace is a type of industrial pretreatment equipment employed to carbonize biomass materials. The main part of the rotary charcoal carbonizing furnace consists of a metal drum with internal flights or louvers. Materials are fed in from the high end and lifted up by inner flights, and when the materials get high enough to fall back off the drum, they fall back to the bottom of the drum. The rotary charcoal carbonizing furnace is popular in the biomass and forestry industries because of their capacity, efficiency, and ability to adapt to new purposes.

The structure of rotary charcoal carbonizing furnace:

Rotary Charcoal Carbonizing Furnace Structure

- Feeder

- Furnace

- Gasifier

- Cyclone

- Gas pipeline

- Gas purifier

- Cooling and discharging device

WORKING PRINCIPLE

When the materials in the furnace are heated to a certain temperature, they begin to carbonize and produce plenty of synthesis gas, which will come through a filtration system to filter out impurities like wood tar and wood vinegar and get combustible gas to be used again to the burner.

RAW MATERIAL

Rotary Drum Dryer Raw Materials

Wood sawdust, wood chips, biomass pellet, coconut fiber, coconut peat, rice husk, bagasse, bamboo shavings, twigs, hemp, coffee husk, walnut shell, sunflower seed shell, etc.

Features for rotary charcoal carbonizing furnace

Difference between Hoisting Carbonization Furnace and Rotary Drum Type Carbonization Furnace/Rotary Charcoal Carbonizing Furnace:

- Hoisting Carbonization Furnace is suitable for wood sticks or biomass rods, while Rotary Drum Type Carbonization Furnace is suitable for powder materials such as sawdust and rice husk.

- Continuous working, no need to stop and change the inner stove, one side for material feeding and the other side for the charcoal outlet.

- High capacity, one machine can get 200-300kg per hour.

- Easy operation, about 2 workers can operate the whole line.